Selecting the correct concrete wedge anchors begins with matching the material to the installation environment. Several key factors to consider guide this critical decision. The global market for these fasteners, including standard Anchor Bolts and custom anchor bolts, was valued at USD 3.56 Billion in 2024 and shows steady growth. A professional custom fasteners manufacturer recognizes that choosing the right wedge anchor is essential for structural integrity.

Key Decision Factors

- Material Composition

- Size and Strength

- Code Compliance

- Installation Method

Properly selecting the anchor’s diameter and length directly impacts project safety and load capacity.

Choosing the Right Material for Concrete Wedge Anchors

The material composition of a wedge anchor is the primary defense against environmental corrosion. A project’s location, exposure to moisture, and contact with chemicals are all critical factors to consider. Selecting the wrong material can lead to premature failure, compromising both the fixture and the safety of the structure.

Carbon Steel Zinc-Plated Anchors

Best for Dry, Indoor Applications

Carbon steel anchors with a zinc-plated finish are the most common and economical choice for interior projects. They provide reliable performance when fastening items in a controlled, dry environment. Common applications include securing shelving, conduit supports, and machinery inside warehouses, office buildings, or residential basements where moisture exposure is minimal.

Understanding Zinc Plating Limitations

Zinc plating offers a basic layer of corrosion protection. The process involves electroplating a thin layer of zinc onto the carbon steel base. This layer acts as a sacrificial coating. It corrodes first, protecting the steel underneath. However, this coating is very thin and easily scratched during installation. Any damage to the plating exposes the carbon steel, making it immediately vulnerable to rust if moisture is present. These anchors are unsuitable for outdoor or damp conditions.

Cost-Effectiveness and Availability

The primary advantage of zinc-plated anchors is their low cost and widespread availability. For high-volume indoor applications where environmental threats are negligible, they offer an excellent balance of strength and affordability. Installers can easily source them from nearly any hardware or industrial supply store.

Hot-Dipped Galvanized (HDG) Anchors

Ideal for Damp or Outdoor Environments

Hot-dipped galvanized (HDG) anchors are designed for environments with moisture, including outdoor settings and damp indoor areas like garages or basements. They provide a significant upgrade in corrosion resistance compared to standard zinc plating, making them suitable for fastening deck posts, fences, and structural ledgers.

The Galvanization Process and Corrosion Resistance

Hot-dip galvanization creates a much thicker, more durable protective layer than zinc plating. The process involves submerging the steel anchor in a bath of molten zinc. This creates a metallurgical bond between the zinc and the steel, resulting in a robust coating that is abrasion-resistant. The thickness of this coating provides a much longer service life in corrosive settings. Key industry standards govern this process to ensure quality.

Note on HDG Specifications Several ASTM standards define the requirements for hot-dip galvanization on fasteners to ensure proper coating thickness, adherence, and performance.

- ASTM A153/A153M: This is the primary specification for hardware and fasteners, ensuring a continuous and uniform zinc coating.

- ASTM F2329: This standard is specifically dedicated to the hot-dip galvanizing process for bolts, screws, and other fasteners.

- ASTM A123/A123M: This covers larger iron and steel products and provides general galvanization requirements.

When to Choose HDG Over Stainless Steel

An HDG wedge anchor is a cost-effective choice for many outdoor projects where the environment is not severely corrosive. It offers a good middle ground between the minimal protection of zinc plating and the higher cost of stainless steel. However, in coastal areas with salt spray or in applications with constant moisture, its lifespan is limited. The zinc coating will eventually deplete, exposing the steel to rust.

| Feature | Stainless Steel (Type 304) | Hot-Dipped Galvanized Steel |

|---|---|---|

| Corrosion Resistance in Coastal Areas | Excellent; ideal for coastal and humid environments, resisting rust formation. | Limited; coatings deteriorate faster in coastal or highly humid areas, leading to rust. |

| Lifespan | Longer lifespan, reducing replacement and maintenance needs. | Shorter lifespan, requiring more frequent replacements. |

Stainless Steel Anchors

Stainless steel concrete wedge anchors offer the highest level of corrosion resistance and are essential for projects demanding longevity and maximum fixture permanence. The two most common types used for anchoring are Type 304 and Type 316.

Type 304 for General Outdoor and Freshwater Exposure

Type 304 stainless steel is an excellent choice for outdoor applications and freshwater environments. It contains chromium and nickel, which create a passive, corrosion-resistant layer on the steel’s surface. This layer self-heals if scratched, providing continuous protection. It is ideal for projects near lakes and rivers or for architectural features exposed to rain.

Type 316 for Marine and Corrosive Chemical Environments

For the most demanding conditions, Type 316 stainless steel is the superior option. Its key advantage comes from the addition of molybdenum to its alloy. This element dramatically increases its resistance to chlorides, acids, and other harsh chemicals.

| Feature | Type 304 Stainless Steel | Type 316 Stainless Steel |

|---|---|---|

| Key Alloying Element | – | Molybdenum |

| Chloride Pitting Resistance | Standard | Enhanced |

| Chemical Resistance | Good | Excellent |

| Cost | Lower | Higher |

Type 316 is the mandatory choice for applications in or near saltwater, such as docks and coastal buildings. It is also specified for wastewater treatment plants, chemical processing facilities, and food-grade environments where harsh cleaning solvents are used. Its enhanced resistance protects against:

- Pitting from chloride solutions (like salt spray)

- Crevice corrosion

- Sulfuric acids and industrial chemicals

Long-Term Performance and Investment

While stainless steel anchors carry a higher initial cost, they represent a long-term investment in safety and durability. Their extended lifespan eliminates the need for costly future replacements and maintenance, especially in inaccessible or critical structural connections. Choosing stainless steel ensures the connection remains secure for the life of the structure.

Specialty Coatings and Alloys for 2026

The world of construction continually evolves. Engineers and builders in 2026 demand anchoring solutions with unprecedented longevity and resilience. Standard materials, while effective for many jobs, sometimes fall short in extremely corrosive or high-stress environments. This need drives the adoption of specialty coatings and advanced alloys, pushing the performance boundaries for concrete wedge anchors.

Advanced Ceramic-Epoxy Coatings

Advanced ceramic-epoxy coatings represent a significant leap forward in fastener protection. Manufacturers apply these specialized coatings over a high-strength carbon steel or stainless steel anchor. The result is a hybrid fastener combining the mechanical strength of steel with a chemically inert, highly durable protective barrier.

This coating technology offers several distinct advantages:

- Exceptional Corrosion Resistance: The ceramic-epoxy layer provides a robust shield against moisture, chemicals, and salt. Its performance often exceeds that of hot-dipped galvanization.

- Superior Abrasion Resistance: The hard ceramic component resists scratches and damage during installation. This quality ensures the protective barrier remains intact.

- Chemical Inertness: These anchors are ideal for industrial settings like chemical plants or wastewater facilities. The coating resists a wide range of acids and alkaline substances.

Expert Tip 💡 Ceramic-epoxy coated anchors provide a cost-effective alternative to solid stainless steel in certain corrosive environments. An installer must handle them with care to avoid deep gouges that could compromise the coating. Always verify the coating’s compatibility with the specific chemical exposure of your project.

These advanced coatings are becoming the standard for critical infrastructure projects. They protect anchors used in bridges, tunnels, and coastal structures where maintenance is difficult and long-term reliability is non-negotiable.

Duplex Stainless Steel Alloys

Duplex stainless steel alloys occupy the pinnacle of anchor material performance. These modern alloys contain a mixed microstructure of both austenite and ferrite. This combination yields properties that are unattainable with conventional Type 304 or 316 stainless steels. The primary benefit of duplex steel is its immense strength and superior resistance to all forms of corrosion.

Key characteristics include:

- Extreme Strength: Duplex stainless steel anchors can have up to twice the yield strength of their austenitic counterparts. This allows for smaller diameter anchors to handle the same load, or for standard-sized anchors to manage significantly higher loads.

- Chloride Stress Corrosion Cracking (SCC) Resistance: This is the standout feature of duplex alloys. They show remarkable resistance to SCC, a failure mechanism that can affect standard stainless steels in warm, chloride-rich environments like swimming pool enclosures or coastal industrial sites.

- Enhanced Pitting and Crevice Corrosion Resistance: Duplex alloys offer a higher level of protection against localized corrosion compared to even Type 316 stainless steel.

The selection of a duplex anchor is reserved for the most demanding and critical applications where failure is not an option.

| Material | Relative Strength | Chloride Corrosion Resistance | Best Use Case |

|---|---|---|---|

| Type 304 SS | Standard | Good | General outdoor, freshwater |

| Type 316 SS | Standard | Excellent | Marine, chemical exposure |

| Duplex SS | Very High | Exceptional | Offshore platforms, submerged tunnels, critical infrastructure |

Engineers specify duplex stainless steel anchors for projects like offshore oil rigs, desalination plants, and architectural elements exposed to harsh marine or industrial pollutants. Their higher upfront cost is justified by unparalleled long-term performance and safety in environments where other materials would quickly fail.

Determining the Correct Size and Strength for Your Wedge Anchor

After selecting the appropriate material, the next critical step involves determining the correct anchor size. The diameter and length of a wedge anchor are not arbitrary. These dimensions directly govern the anchor’s load-bearing capacity and ensure a secure connection between the fixture and the concrete base material. An incorrect size can lead to installation failure or, in a worst-case scenario, a catastrophic connection failure.

Calculating Required Anchor Diameter

The anchor’s diameter is its primary source of strength. A larger diameter provides greater resistance to both shear and tensile forces. The selection process begins by evaluating the fixture itself and the loads it will be subjected to.

Matching Diameter to Fixture Hole Size

The first constraint on anchor diameter is the hole in the object being fastened. The hole in the fixture must always be larger than the anchor’s designated diameter. This clearance allows the anchor to pass through the fixture easily during installation. For instance, a 5/8″ diameter wedge anchor requires a 7/8″ hole in the fixture. This oversized hole is standard practice and ensures the anchor can be set without obstruction.

Understanding Shear and Tensile Loads

An anchor is subjected to two primary types of forces. Understanding them is fundamental to selecting the correct diameter.

- Tensile Load (Pull-Out Force): This is the force that tries to pull the anchor straight out of the concrete. Examples include hanging signs or suspended piping.

- Shear Load (Sideways Force): This is the force that runs parallel to the concrete surface, trying to slice the anchor. A common example is a ledger board bolted to a foundation wall.

A larger anchor diameter provides a greater cross-sectional area of steel, which significantly increases its capacity to resist both shear and tensile loads.

Common Diameters for Standard Applications

For many everyday projects, a few standard diameters are sufficient. Installers frequently use these sizes for light to medium-duty fastening.

- 1/4″ & 3/8″: Ideal for very light-duty applications like securing electrical conduit straps, lightweight shelving, and signage.

- 1/2″: A versatile, all-purpose diameter used for anchoring pallet racking, machinery, and 2×4 lumber.

- 5/8″: A step up for more substantial loads, such as securing heavier equipment or structural posts.

Heavy-Duty Applications and Larger Diameters

Structural applications and the fastening of heavy machinery demand larger, more robust anchors. Diameters of 3/4″, 1″, and even 1-1/4″ are specified for these critical connections. They are used for securing structural steel columns, large industrial equipment, and elements in high-seismic zones where maximum strength is non-negotiable. The weight of the load is a primary driver for specifying these larger sizes.

Selecting the Proper Anchor Length

Choosing the correct anchor length is a straightforward calculation. The goal is to ensure the anchor achieves the required embedment depth while also passing completely through the fixture with enough thread exposed for the nut and washer.

The Embedment Depth Formula

The length of a concrete wedge anchor is determined by adding the thickness of the material being fastened, the required embedment depth, and the space needed for the nut and washer. The standard formula is simple:

- FT + ME + NW = MLWA

- FT: Fixture Thickness

- ME: Minimum Embedment

- NW: Nut & Washer Height

Factoring in Fixture Thickness

The calculation starts with the thickness of the material being fastened. For example, if a standard 2×4 is being fastened to concrete, its actual thickness is 1-1/2″. This becomes the “FT” value in the formula. Using this example with a 1/2” wedge anchor, the minimum length would be calculated as: 1-1/2” (2×4) + 2-1/4” (minimum embedment) + 1/2” (space for nut and washer) = 4-1/4”. Therefore, the shortest 1/2” diameter wedge anchor for this application would be 4-1/4”.

Accounting for Nut and Washer Height

After the anchor passes through the fixture and is embedded in the concrete, there must be enough threaded portion remaining to fully engage the nut and washer. A reliable rule of thumb is to add a space equal to the anchor’s diameter. For a 1/2″ anchor, add 1/2″ for the nut and washer. For a 3/4″ anchor, add 3/4″.

Minimum Embedment vs. Optimal Embedment

Every wedge anchor diameter has a specified minimum embedment depth required to achieve its published holding values. Installing an anchor shallower than this depth will severely compromise its performance. However, deeper embedment can often increase an anchor’s capacity.

| Concept | Description | Implication |

|---|---|---|

| Minimum Embedment | The shallowest depth at which the anchor is engineered to function and meet its listed load values. | This is a mandatory requirement. Failure to achieve minimum embedment results in an unsafe installation. |

| Optimal Embedment | A deeper embedment that can provide higher pull-out resistance, especially in lower-strength concrete. | While not always required, deeper embedment provides an additional margin of safety and can improve performance. |

Always consult the manufacturer’s specifications for the exact minimum embedment depth for the diameter you are using.

Understanding Load Capacities

The ultimate strength of an anchor installation depends on more than just the anchor itself. It is a system that includes the anchor, the quality of the concrete, and the installation geometry.

Reading Manufacturer Load Charts

Manufacturers provide detailed technical data sheets that list the ultimate tensile and shear load capacities for their anchors. These charts are typically organized by anchor diameter and embedment depth. An installer must reference these charts to verify that a chosen anchor can handle the calculated loads for the application.

The Role of Concrete Compressive Strength (PSI)

Anchor load capacities are not absolute. They are directly tied to the compressive strength of the concrete, measured in Pounds per Square Inch (PSI). A wedge anchor installed in 5,000 PSI concrete will have a significantly higher holding value than the same anchor installed in 2,500 PSI concrete. Manufacturer charts often provide load values for different concrete strengths.

Applying Safety Factors for Static and Dynamic Loads

Manufacturer charts list “ultimate” load values, which represent the point of failure. For safe design, engineers apply a safety factor to determine the “allowable” or “safe working” load. A common safety factor is 4, meaning the safe working load is 25% of the ultimate load.

Safety First ⚠️ The safety factor should be increased for dynamic loads (vibrations from machinery, wind, or seismic activity) or for overhead applications where failure could be life-threatening. Always consult an engineer for critical applications.

Edge and Spacing Distance Considerations

Proper installation requires knowing how to measure spacing between anchors and from an edge. Placing anchors too close to a concrete edge or too close to each other can cause the concrete to crack and fail, a condition known as “cone failure.” Manufacturers specify minimum edge and spacing distances. Adhering to these guidelines is one of the key factors to consider for a safe installation. Following these rules is essential for how to achieve holding value and prevent premature failure of the concrete itself.

A Look at Different Types of Concrete Anchors and Their Compliance

Beyond material and size, an anchor’s compliance with building codes is a non-negotiable aspect of safe construction. Professional installers must verify that the selected concrete wedge anchors meet the specific requirements of the job, which often involves navigating technical reports and industry standards. Understanding these compliance documents ensures the installation is both legal and structurally sound. There are many types of concrete anchors available, each with specific compliance standards.

The Importance of ICC-ES Reports

The International Code Council Evaluation Service (ICC-ES) provides technical evaluations of building products. These reports are critical for ensuring an anchor meets code requirements.

What is an ICC-ES Report?

An ICC-ES report is a document that confirms a product, like a wedge anchor, complies with building codes. It provides engineers and inspectors with verified data on the anchor’s performance. The report details load capacities, installation parameters, and approved uses, serving as a trusted third-party validation of the manufacturer’s claims.

How to Find and Read an ESR Number

Every ICC-ES report has a unique Evaluation Service Report (ESR) number. Manufacturers typically list this number on their product packaging and technical data sheets. An installer can look up the ESR number on the ICC-ES website to access the full report. This document contains all the critical performance data needed for proper specification and inspection.

Cracked vs. Uncracked Concrete Ratings

ICC-ES reports for different types of concrete anchors specify their suitability for either cracked or uncracked concrete.

- Uncracked Concrete: This refers to concrete that is not expected to crack under service loads.

- Cracked Concrete: This is concrete in a tension zone, where hairline cracks may form. Anchors rated for cracked concrete are designed to maintain their holding power even if a crack develops at the installation point.

Seismic Ratings and Requirements

In regions prone to earthquakes, anchors must meet stringent seismic requirements to ensure they can withstand dynamic forces.

Understanding Seismic Design Categories (SDC)

Building codes classify structures into Seismic Design Categories (SDC) from A to F, based on location and occupancy. Structures in higher categories (C and above) require anchoring systems with proven seismic performance. The SDC dictates which types of concrete anchors are permissible.

ACI 318 and Seismic Prequalification

The American Concrete Institute’s ACI 318 building code outlines the testing procedures for prequalifying anchors for seismic applications. Anchors must pass a series of simulated seismic tests to prove they can resist cyclic loading without failure. Only anchors that have undergone this rigorous testing receive a seismic rating.

When Are Seismic-Rated Anchors Mandatory?

Seismic-rated anchors are mandatory in structures falling under SDC C or higher. This includes critical facilities like hospitals and schools, as well as many commercial and residential buildings in earthquake-prone areas. Using non-rated anchors in these applications is a serious code violation and safety hazard.

Head Stamping and Identification

Manufacturers stamp identification marks directly onto the anchor head. These markings allow for easy post-installation verification of the anchor’s properties.

Decoding Markings on the Anchor Head

The markings on an anchor head provide a quick reference for inspectors. They can identify the manufacturer, material, and anchor length without needing to remove the fastener. This system ensures accountability and simplifies the inspection process.

Length Identification Codes

Many manufacturers use a simple system to identify anchor length.

- Some brands, like Conquest, stamp a letter on the head that corresponds to a specific length range.

- Other manufacturers, such as Trubolt, stamp the exposed end of the anchor to identify its length.

Manufacturer and Material Markings

The head stamp also includes codes for the material and manufacturer.

- A manufacturer’s unique symbol or initials are typically present.

- Material markings are also common. For example, metric bolts made of 304 stainless steel are often marked with ‘A2-70’ to signify the material grade and strength class.

Emerging 2026 Building Code Updates

Building codes are not static documents. They evolve to reflect new research, materials technology, and a deeper understanding of structural safety. Professionals in 2026 must stay informed about key updates that influence product selection and installation methods. Two significant trends shaping anchor compliance are enhanced fire resistance standards and stricter regulations on material emissions. These changes affect the specification of many types of concrete anchors for modern construction projects.

New Fire Resistance Standards (ASTM E119)

Fire safety engineering continues to advance, placing greater emphasis on the performance of all building components during a fire. The updated focus on ASTM E119, the “Standard Test Methods for Fire Tests of Building Construction and Materials,” directly impacts anchor selection. This standard evaluates how long a structural connection can withstand extreme heat while maintaining its load-bearing capabilities. An anchor’s performance under fire conditions is now a critical data point for life-safety applications.

Life-Safety Implications ⚠️ In a fire, the failure of an anchor supporting fire sprinkler pipes, electrical conduit, or ventilation systems can be catastrophic. It can disable emergency systems and create dangerous falling debris, hindering evacuation and emergency response efforts.

By 2026, building codes will mandate fire-rated anchors for an increasing number of applications. These include egress pathways, high-occupancy areas, and supports for critical systems. Installers must consult an anchor’s technical data sheet for specific ASTM E119 compliance information. This requirement will guide the selection between different types of concrete anchors, ensuring the chosen product is qualified for the fire-resistance rating of the surrounding assembly.

Updated Regulations for Low-VOC Materials

The construction industry’s shift toward sustainability and healthier indoor environments has led to stricter rules regarding Volatile Organic Compounds (VOCs). VOCs are chemicals emitted from certain materials that can negatively impact indoor air quality. While a standard mechanical wedge anchor is inherently zero-VOC, this regulation becomes important when considering specialty coatings or comparing different types of concrete anchors, such as adhesive systems.

The push for low-VOC materials comes from several sources:

- Green Building Standards: Programs like LEED (Leadership in Energy and Environmental Design) award points for using materials with low or no VOC emissions.

- Health and Wellness: There is growing awareness of the health risks associated with poor indoor air quality, especially in sensitive environments.

- Government Regulations: Jurisdictions are increasingly adopting stricter limits on the VOC content of construction products.

For projects in 2026, particularly schools, hospitals, and residential buildings, specifiers must verify that all components meet these low-VOC requirements. This means checking the product data for any specialty-coated anchors to ensure their protective layer is chemically stable and does not off-gas. This due diligence ensures the final installation is not only structurally sound but also contributes to a safe and healthy indoor environment for occupants.

Proper Installation of Expansion Concrete Anchors for Maximum Safety

An installer’s skill is just as crucial as the quality of the anchor itself. A correctly chosen anchor can fail if the installation process is flawed. Following a systematic procedure for installing expansion concrete anchors is essential for achieving the manufacturer’s specified load capacities and ensuring long-term structural safety. This process begins long before the anchor enters the concrete.

Pre-Installation Checklist

A successful installation starts with proper preparation. A pre-installation checklist helps an installer confirm that the site conditions are appropriate, all necessary tools are on hand, and safety measures are in place.

Verifying Concrete Condition and Age

The installer must first inspect the concrete base material. It should be free of large cracks, spalls, or other visible defects. The age of the concrete is also a critical factor. Mechanical anchors exert significant expansion forces, and installing them in “green” or uncured concrete can cause the base material to fracture.

Concrete Curing Time ⏱️

- Minimum Wait: Professional guidelines recommend waiting at least 7 days before installing anchors, as the concrete will have reached approximately 75% of its design strength.

- Ideal Wait: For structural applications, waiting the full 28-day curing period is the best practice to ensure maximum holding power.

- Avoid: Installing a wedge anchor in concrete less than 7 days old risks a weak connection due to the concrete’s pliability.

Assembling the Right Tools

Having the correct tools ready streamlines the installation and prevents costly errors. A professional installer’s toolkit for this task should include:

- Rotary hammer drill

- ANSI-compliant carbide drill bit

- Wire brush (sized to the hole diameter)

- Compressed air source or hand pump

- Calibrated torque wrench

- Tape measure

- Hammer

Personal Protective Equipment (PPE)

Safety is paramount. Drilling into concrete creates fine silica dust, which is a serious respiratory hazard. Flying debris also poses a risk.

Safety First 👷 Always wear the following PPE during anchor installation:

- Eye Protection: Safety glasses or goggles are mandatory.

- Respiratory Protection: An N95-rated respirator is essential to protect against silica dust.

- Hearing Protection: A rotary hammer drill produces high noise levels.

- Gloves: Protect hands from abrasion and sharp edges.

Drilling the Hole Correctly

The quality of the drilled hole directly impacts the anchor’s performance. The diameter, depth, and cleanliness of the hole must be precise. Learning how to drill hole correctly is a fundamental skill.

Choosing the Right Carbide Drill Bit Size

The diameter of the drill bit must match the diameter of the anchor being installed. For example, a 1/2″ diameter anchor requires a 1/2″ diameter hole. Using an oversized bit will result in a loose fit and prevent the anchor from expanding properly. An undersized bit will make installation impossible.

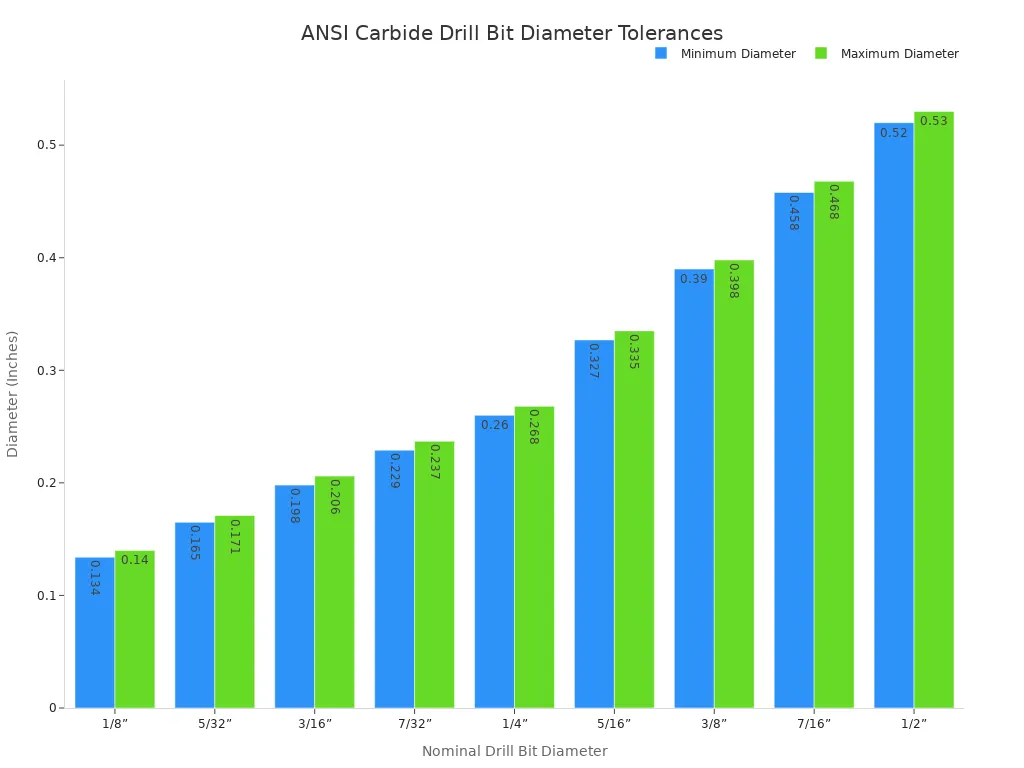

ANSI Standards for Drill Bits

Professional installers use carbide-tipped drill bits that meet the American National Standards Institute (ANSI) B212.15 standard. This standard ensures the bit’s diameter is within a strict tolerance range, guaranteeing the hole is the correct size for optimal anchor performance.

Achieving the Correct Hole Depth

The hole must be drilled deeper than the anchor’s required embedment depth. This extra space accommodates the concrete dust that settles at the bottom during drilling. A good rule of thumb is to drill the hole at least one anchor diameter deeper than the planned embedment. Knowing how to drill hole to the proper depth is key for a secure fit.

Hole Cleaning Procedures

A clean hole is absolutely essential for a safe and reliable anchor installation. This step is often rushed or skipped, leading to significantly reduced performance.

Why Hole Cleaning is Non-Negotiable

Concrete dust left in the hole acts as a lubricant. It prevents the anchor’s expansion clip from properly gripping the walls of the concrete. This lack of friction can reduce the anchor’s holding power by a significant margin. A clean hole ensures direct contact between the anchor and the base material.

The Wire Brush and Compressed Air Method

The industry-standard cleaning procedure is the “brush-and-blow” method.

- Blow: Use compressed air to blow out the loose dust from the hole. While some technical guides specify 90 PSI, OSHA safety standards cap handheld cleaning pressure at 30 PSI.

- Brush: Insert a properly sized wire brush and scrub the walls of the hole to dislodge any remaining dust.

- Blow Again: Use compressed air a second time to remove the loosened particles.

Consequences of an Improperly Cleaned Hole

Failing to clean the hole has severe consequences. The anchor may spin freely in the hole during tightening, never achieving proper expansion. This completely negates its holding power. In some cases, the anchor may feel tight, but its capacity could be reduced by as much as 25%, creating a hidden and dangerous point of failure.

Anchor Installation and Torquing

The final stage of the installation process involves setting and tightening the anchor. This mechanical action creates the expansion force that locks the anchor into the concrete. Precision during this step is critical for developing the anchor’s full strength.

Setting the Anchor to the Correct Embedment

An installer first drives the anchor through the fixture and into the clean, pre-drilled hole. A hammer is used to tap the anchor until the nut and washer are snug against the fixture’s surface. The installer must ensure the anchor reaches its required minimum embedment depth. Driving the anchor too shallow prevents the expansion clip from engaging a sufficient amount of concrete, which severely compromises its strength. Achieving the correct minimum embedment is a non-negotiable part of the process.

Using a Calibrated Torque Wrench

Tightening the nut is what activates the anchor. As the nut turns, it pulls the tapered cone at the bottom of the anchor up into the expansion clip. This action forces the clip outward, creating a friction hold against the walls of the hole. A calibrated torque wrench is the only tool that can apply the precise rotational force needed for this task. Using a standard wrench or an impact driver invites guesswork and often leads to improper loading.

Manufacturer’s Recommended Torque Values

Every anchor manufacturer provides a specific installation torque value for each anchor diameter. This value is the result of extensive testing. It represents the ideal force needed to set the anchor without damaging the concrete or the anchor itself. These values are published in the anchor’s technical data sheet and often on the product packaging. Adhering to these recommendations is the only way how to achieve holding value reliably.

Avoiding Over-Torquing and Under-Torquing

Applying the correct torque is a balancing act. Under-torquing fails to expand the clip sufficiently, resulting in low holding power and potential anchor pullout failure. Over-torquing is equally dangerous and can cause several types of failure.

- Concrete failure: Excessive expansion force can crack or break the surrounding concrete.

- Steel failure of the anchor: The bolt can stretch beyond its yield point or even snap.

- Damage to the plate being clamped: The force can bend or deform the fixture.

Proper installation of expansion concrete anchors requires following these steps meticulously. A calibrated torque wrench ensures the connection is both secure and safe, preventing the catastrophic failures associated with improper force application.

A buyer follows four key steps for success: choosing the material, sizing the anchor, verifying compliance, and planning the process. A final checklist helps guide the purchase.

Buyer’s Checklist

- Environment: Match material to exposure.

- Load: Select diameter and length for strength.

- Code: Confirm compliance and ratings.

- Process: Plan the installation steps.

Correctly chosen concrete wedge anchors are fundamental to structural safety. A proper wedge anchor ensures project longevity. When in doubt, an installer should always consult an engineer or the manufacturer’s technical support.

FAQ

Can an installer reuse a concrete wedge anchor?

No. An installer must never reuse a wedge anchor. The expansion clip deforms permanently during the initial installation. Removing the anchor damages this clip, making a second installation unsafe and unreliable. Always use a new anchor for every connection to ensure safety.

What happens if the hole is drilled too big?

An oversized hole prevents the anchor’s expansion clip from properly gripping the concrete walls. The anchor will not achieve its required holding power. The installer must abandon the oversized hole and drill a new one in a different, approved location.

Is it okay to use an impact wrench to tighten a wedge anchor?

An installer should not use an impact wrench. These tools cannot apply a precise torque value and often lead to over-torquing, which can damage the anchor or concrete. A calibrated torque wrench is the only professional tool for achieving the correct installation torque.

How close to a concrete edge can an anchor be placed?

The minimum edge distance depends on the anchor’s diameter and embedment depth. Manufacturers provide this critical data in their technical specifications or ICC-ES reports. Following these guidelines prevents the concrete from cracking and causing a connection failure. Always check the manufacturer’s data.

Why did my anchor just spin in the hole when I tried to tighten it?

A spinning anchor usually indicates an improperly cleaned or oversized hole. Concrete dust prevents the clip from gripping the wall. The installer should remove the anchor, thoroughly clean the hole using the brush-and-blow method, and then attempt the installation again.

Do I need a special drill bit to install wedge anchors?

Yes. Professionals use carbide-tipped drill bits that meet ANSI B212.15 standards. These bits guarantee the hole diameter is within the correct tolerance for optimal anchor performance. Using a non-compliant or worn bit can compromise the entire installation and its holding value.

How long must I wait to install anchors in new concrete?

Curing Time is Critical ⏱️ An installer should wait a minimum of 7 days before installing anchors. For maximum strength in structural applications, waiting the full 28-day curing period is the best practice. This ensures the concrete can withstand the anchor’s expansion forces.