The Alden Grabit Pro Kit is the best overall bolt extractor set for 2026. Its dual-ended design and durability set a high standard. The global hand tools market is projected to grow at a 5.7% CAGR, showing a rising demand for reliable tools. A quality bolt extractor is crucial for removing a damaged установить болт, even one from a производитель крепежных изделий на заказ. This extractor kit handles issues from poor литье болтов to stripped нестандартные крепежные элементы. Below is a comparison of the best bolt extractor sets.

| Продукция | Наилучшее применение | Ключевая особенность |

|---|---|---|

| Alden Grabit Pro Kit | Overall Use | Dual-End Drill & Extract |

| Topec Impact Set | High Torque | Impact-Rated Cr-Mo Steel |

| IRWIN HANSON Set | Budget DIY | Aggressive Spiral Flutes |

| Mayhew ProGrip Set | Hardened Bolts | Straight Flute Design |

| RocketSocket Set | Rounded Hex Heads | Helical Socket Grip |

Detailed Reviews of the Top 5 Best Bolt Extractor Sets for 2026

Choosing the right tool can turn a frustrating repair into a satisfying success. A stuck or damaged fastener is a common roadblock for professionals and DIYers alike. This section provides an in-depth analysis of the top-performing screw extractor sets, helping you select the perfect tool for your needs. We evaluated each set on performance, durability, and overall value.

1. Alden Grabit Pro Kit – Best Overall

The Alden Grabit Pro Kit earns its top spot by offering a brilliantly simple and effective solution. Its unique two-step process makes it the best screw extractor for a wide range of applications, from woodworking to automotive repairs. This extractor kit has been a market leader since its introduction in 2006.

Dual-Action Performance Analysis

The Grabit Pro’s genius lies in its dual-ended bit design. One end is a burnisher (drill) that smooths and prepares the head of a damaged fastener. You then flip the bit to use the extractor end. This self-centering screw extractor tip bites into the prepared surface, providing a strong grip for removal. This system works exceptionally well on a stripped screw and various fastener types, including Phillips, Torx, and hex. The process is fast, intuitive, and highly reliable.

Material Durability and Wear Resistance

Alden constructs the Grabit Pro bits from M2 High-Speed Steel (HSS). This material is hardened twice to a Rockwell hardness of 62-63 HRC, ensuring excellent wear resistance and a long service life. The quality construction means each screw extractor can handle repeated use on tough fasteners without dulling or breaking. Proudly made in the USA, Alden backs these tools with a full lifetime warranty, showcasing their confidence in the product’s durability.

Примечание: While designed for variable-speed reversible drills, the Grabit Pro also works effectively with a standard 1/4-inch hex screwdriver for lower-torque applications.

Included Sizes and Case Quality

The standard Alden 8440P Grabit Pro is a 4-piece set that has become a #1 best seller. It comes in a compact, durable case that clearly labels each bit size. For those needing more versatility, the Alden 1007P Master Extractor Grabit® Pro 10 Piece Kit offers a comprehensive range for more demanding jobs.

| Характеристика | Спецификация |

|---|---|

| Model | Alden 8440P Grabit Pro |

| Материал | M2 HSS (Hardened) |

| Pieces | 4-Piece Set |

| Размер болта | Up to 3/8-inch (10mm) |

| Fastener Length | Up to 4 inches long |

| Drill Compatibility | 3/8-inch drill, 1/4-inch hex |

Pros & Cons

- Pros:

- ✅ Innovative two-step drill and extract design.

- ✅ Made from durable, double-hardened M2 HSS.

- ✅ Works on a wide variety of fastener types and materials.

- ✅ Backed by a lifetime warranty and made in the USA.

- Cons:

- ❌ Not rated for use with impact drivers.

- ❌ Higher price point than basic spiral extractors.

2. Topec Impact Bolt & Nut Remover Set – Best for High-Torque Applications

When you need sheer power, the Topec Impact Bolt & Nut Remover Set delivers. This set is specifically engineered to work with impact wrenches and drivers, making it the ideal choice for automotive technicians and heavy machinery mechanics dealing with rusted, frozen, or over-torqued fasteners.

Impact Wrench Performance

These sockets are built to withstand the intense, repeated rotational force of an impact wrench. Each bolt extractor features a high-torque, 6-point design that grips the outside of a damaged bolt or nut head. In our tests, the Topec set effortlessly removed lug nuts and suspension bolts that other extractors failed to budge. The 3/8-inch square drive is compatible with most common impact tools and ratchets.

Design Comparison: Multi-Spline vs. Spiral

Unlike a traditional spiral screw extractor that bites internally, the Topec set uses an external multi-spline (or helical) socket design. This approach offers two key advantages:

- No Drilling Required: It saves time and eliminates the risk of breaking a drill bit inside the fastener.

- Superior Grip on Rounded Heads: The internal splines bite deeper into a rounded-off hex head as more torque is applied.

This makes it one of the best bolt extractor sets for externally damaged fasteners.

Extreme Torque Durability Test

We subjected the Topec set to extreme conditions, using it on grade 8 bolts seized with rust. The sockets, made from high-hardness Chrome Molybdenum (Cr-Mo) steel, showed no signs of cracking, stripping, or deforming. The black oxide finish provides an extra layer of corrosion resistance, ensuring the tool remains reliable job after job.

Pros & Cons

- Pros:

- ✅ Impact-rated for use with high-torque tools.

- ✅ Durable Cr-Mo steel construction.

- ✅ Excellent grip on rounded-off nuts and bolt heads.

- ✅ No drilling needed for external fasteners.

- Cons:

- ❌ Only works on externally accessible heads; not for recessed bolts.

- ❌ Less effective on fasteners with completely sheared-off heads.

3. IRWIN HANSON Screw Extractor Set – Best Budget Screw Extractor Set

For DIY enthusiasts and homeowners who need a reliable tool without a professional price tag, the IRWIN HANSON Screw Extractor Set is an unbeatable value. This set provides solid performance for common household and workshop tasks, proving that you do not need to spend a fortune for an effective screw extractor.

Value Analysis: Performance vs. Price

This screw extractor set offers impressive gripping power for its low cost. The aggressive spiral flute design is engineered to embed itself deeper into the metal as you apply counter-clockwise torque. This allows the screw extractor to create a strong bite inside a drilled pilot hole. While it may not have the advanced features of premium models, it performs its core function exceptionally well, making it a smart investment for occasional use.

Material Quality for the Price

IRWIN constructs these extractors from carbon steel, which provides adequate hardness for most soft-to-medium grade screws and bolts found in furniture, appliances, and general construction. The material is not intended for hardened or high-strength automotive bolts, but it offers excellent durability for its target applications. The tool’s performance far exceeds its budget-friendly price point.

Ideal Use Cases for DIYers

This bolt extractor is perfect for projects around the house. Think of tasks like:

- Removing a stripped screw from a deck board.

- Extracting a broken bolt from a piece of assemble-it-yourself furniture.

- Fixing outdoor equipment with damaged Phillips or flathead screws.

It is a must-have addition to any home toolbox for handling unexpected repairs quickly and efficiently.

Pros & Cons

- Pros:

- ✅ Excellent performance for a very low price.

- ✅ Aggressive spiral design provides a strong grip.

- ✅ Covers a useful range of common small fastener sizes.

- ✅ Simple and easy to use with a standard tap wrench.

- Cons:

- ❌ Not suitable for hardened steel bolts.

- ❌ Carbon steel is more brittle than HSS or Cr-Mo.

4. Mayhew Tools ProGrip Set – Best for Hardened Bolts

When dealing with high-strength, heat-treated, or alloy steel fasteners, a standard screw extractor can fail. The Mayhew Tools ProGrip Set is engineered specifically for these challenging situations. Its robust design and material make it the top choice for mechanics and industrial maintenance professionals who encounter hardened bolts.

Effectiveness on High-Grade Fasteners

The ProGrip set excels where others break. These tools are forged from alloy steel and heat-treated for maximum hardness and strength. This allows the screw extractor to bite into Grade 8 or even stronger fasteners without chipping or shattering. During testing, this bolt extractor successfully removed broken manifold bolts and suspension components that were notoriously difficult. Its performance on hardened materials is its defining feature.

Straight Flute Design for Maximum Bite

Unlike spiral designs, the ProGrip utilizes a straight flute (or straight lobe) design. This offers a distinct advantage for hardened materials.

- Less Expansion: The straight flutes do not expand the bolt outward as much as a tapered spiral screw extractor. This reduces the risk of making a seized bolt even tighter.

- Maximum Surface Contact: The design allows for more surface area to grip the inside of the drilled pilot hole, providing a powerful, non-slip bite.

Требуемый диаметр твердосплавного сверла For this type of screw extractor, a perfectly centered and correctly sized pilot hole is critical for success. Take extra time during the preparation step.

Usability with T-Handles and Wrenches

Each screw extractor in the set features a square drive head. This universal design allows for use with a variety of turning tools. You can use a standard tap handle for precise, controlled torque application. For more stubborn bolts, you can use an adjustable wrench or a matching socket and ratchet. This versatility makes the bolt extractor adaptable to different scenarios and available tools in the workshop.

Pros & Cons

- Pros:

- ✅ Specifically designed for hardened and high-grade bolts.

- ✅ Durable alloy steel construction resists breaking.

- ✅ Straight flute design provides a strong grip with less expansion.

- ✅ Compatible with tap handles, sockets, and wrenches.

- Cons:

- ❌ Requires a very precise pilot hole for optimal performance.

- ❌ Not recommended for softer materials, as it can be overly aggressive.

5. RocketSocket Extraction Set – Best for Rounded Hex Heads

A rounded or stripped hex head is a common and frustrating problem. The RocketSocket Extraction Set provides a brilliant external-grip solution, making it one of the best bolt extractor sets for this specific issue. It saves time by eliminating the need for drilling.

Grip on Externally Damaged Bolts

The RocketSocket shines where a standard socket slips. It is designed to grip the outside of a fastener head, even one that is up to 85% rounded off. This makes it the perfect tool for removing a stripped screw, a weathered lug nut, or any bolt where the hex flats have been compromised. The more torque you apply, the deeper the socket bites, creating a secure connection that will not let go. This screw extractor is a lifesaver for automotive and plumbing repairs.

Helical Socket Design Explained

The magic behind the RocketSocket is its patented helical tooth design. Imagine sharp, tapered teeth spiraling inward. When you place the socket over a damaged head and turn it counter-clockwise, these teeth dig into the metal. This design provides multiple points of contact and continuously tightens its grip as resistance increases. This screw extractor works on a wide range of fastener types, including:

- Hex bolts and nuts

- Socket head cap screws

- Star and Torx screws

This versatile extractor kit is a valuable addition to any professional’s toolbox.

Compatibility with Ratchets and Impact Drivers

RocketSocket designs its tools for real-world use. Each screw extractor socket features a standard 3/8-inch or 1/2-inch square drive, making it compatible with most ratchets, breaker bars, and impact drivers. The sockets are made in the USA from hardened S2 tool steel, giving them the strength to withstand the high torque of an impact wrench. This compatibility makes the removal process fast and efficient. This bolt extractor is built for power.

Pros & Cons

- Pros:

- ✅ Exceptional grip on severely rounded external hex heads.

- ✅ No drilling required, saving time and effort.

- ✅ Impact-rated S2 steel construction for high-torque applications.

- ✅ Made in the USA and backed by a lifetime warranty.

- Cons:

- ❌ Cannot be used on fasteners with completely sheared-off heads.

- ❌ Requires the fastener head to be accessible.

Key Criteria for Choosing Your Next Bolt Extractor Set

Selecting the right bolt and screw extractor set depends on the types of fasteners you encounter and the tools you own. Understanding the key differences in design, material, and size will help you make an informed investment. This guide breaks down the essential criteria for choosing the perfect tool for your needs.

Extractor Type: Which Design Is Right for You?

The design of a screw extractor dictates its application and effectiveness. Each style offers unique advantages for specific removal scenarios.

Spiral Flute Extractors

This is the most traditional screw extractor design. It features aggressive, left-hand spiral flutes that bite into a pre-drilled pilot hole. As you turn the tool counter-clockwise, it embeds itself deeper, generating the grip needed for removal.

- Primary Uses: Removing broken, stripped, or rusted screws in automotive, woodworking, and plumbing applications.

- Limitations: Standard versions are not suited for hardened steel. Their brittle nature can cause them to snap under extreme torque.

Multi-Spline and Helical Socket Extractors

These tools grip the outside of a damaged nut or bolt head. This design eliminates the need for drilling. Multi-spline and helical sockets are particularly effective for stripped Allen bolts and rounded hex heads. One user found great relief using this type of screw extractor in a tight spot.

I bought my kit because I also found myself in a “tight” spot with few good choices. The extractor tool worked for me. I smiled with relief as opposed to a bitter knashing of teeth.

Straight Flute Extractors

A straight flute bolt extractor uses vertical lobes instead of a spiral. You tap it into a pilot hole, and its shape provides multiple points of contact for a powerful grip. This design is ideal for harder materials because it creates less outward expansion, reducing the risk of tightening a seized bolt. This type of screw extractor requires a precise pilot hole.

Drill-Out (Burnisher) Extractors

This innovative screw extractor design, seen in the Alden Grabit Pro, combines two steps into one bit. One end is a burnisher that drills and preps the damaged fastener head. You then flip the bit to use the extractor end, which bites into the newly prepared surface. This makes for a very efficient screw extractor and drill bit set.

Material and Durability: What Are Your Tools Made Of?

The material of a bolt extractor determines its strength, hardness, and lifespan. High-quality materials resist wear and withstand high torque.

Chrome Molybdenum (Cr-Mo)

Cr-Mo steel is known for its toughness and ductility. It can flex slightly under extreme stress, making it perfect for impact-rated screw extractor sets. It typically has a Rockwell hardness between 40-58 HRC.

S2 Tool Steel

S2 tool steel offers excellent shock resistance, making it another great choice for impact tools. It is harder than Cr-Mo, often rating between 56-58 HRC, providing a good balance of strength and durability.

High-Speed Steel (HSS)

HSS is exceptionally hard, often reaching 60-66 HRC. This hardness gives it superior wear resistance, allowing a screw extractor to maintain a sharp edge through repeated use on standard fasteners.

Cobalt Blends

Adding cobalt to HSS (creating M35 or M42 steel) significantly increases heat resistance and hardness (65-67 HRC). A cobalt screw extractor can drill into high-grade bolts. However, this increased hardness also makes the tool more brittle.

Size Range and Compatibility

A bolt extractor set is only useful if it contains the size you need. Professionals and DIYers have different requirements for set size and quality.

| Factor | Professional Use | DIY Projects |

|---|---|---|

| Frequency of Use | Encounters seized bolts daily | Assembling furniture occasionally |

| Fastener Sizes | Wide range, comprehensive set | Covers most common sizes |

| Budget | May invest in higher quality | Cost-effective sets preferred |

Covering Common SAE Sizes

For work on domestic vehicles and older machinery, a set covering standard Society of Automotive Engineers (SAE) or imperial sizes is essential.

Covering Common Metric Sizes

Metric fasteners are the standard for most modern cars, electronics, and equipment worldwide. Most general-purpose screw extractor sets include common metric sizes.

Importance of a Comprehensive Set

While buying a single screw extractor is possible, investing in a comprehensive set ensures you are prepared for any challenge. A quality kit provides long-term durability and peace of mind, preventing a minor repair from becoming a major headache.

Drive Type and Tool Compatibility

The effectiveness of a bolt extractor often depends on the tools you use to turn it. The extractor’s drive type determines its compatibility with your existing toolset, from manual wrenches to powerful impact drivers. Understanding these drive types ensures you can apply the right amount of torque for a successful extraction.

Hex Drive for Wrenches and Sockets

Many extractors feature a hexagonal drive head or base. This design offers excellent versatility for applying manual torque. The flat sides of the hex head provide a secure gripping surface for a wide range of common workshop tools. This adaptability makes them a favorite for many mechanics and DIYers.

- Users can apply force with flat wrenches, pliers, or an adjustable wrench.

- The hex shape also allows for the use of standard sockets with a ratchet.

This multi-tool compatibility means you can almost always find a way to turn the extractor, even in tight spaces.

Square Drive for Tap Handles

Some extractors, particularly straight flute and smaller spiral designs, use a square drive head. This shape is specifically designed to fit into a T-handle or a standard tap wrench. This combination gives the user exceptional control over the tool. Applying slow, steady, and even pressure is critical to prevent the extractor from breaking inside the bolt. The square drive and tap handle pairing provides the tactile feedback needed for these delicate operations.

Требуемый диаметр твердосплавного сверла Always use a tap handle with a square drive extractor when possible. It helps you feel the extractor bite and prevents the application of sudden, uneven force that could snap the tool.

Impact-Rated Designs

For the toughest jobs involving rusted or seized fasteners, an impact-rated extractor is essential. These tools are engineered to withstand the intense, rapid rotational force generated by power tools. They are typically made from durable materials like Chrome Molybdenum (Cr-Mo) steel. Using a non-impact-rated extractor with an impact wrench will likely cause it to shatter, creating a much bigger problem.

Impact-rated sets often feature a dual-compatibility design to handle any situation.

- A 3/8″ or 1/2″ square drive allows direct connection to hand ratchets, air ratchets, and impact wrenches. 🔩

- Many also include hexagonal flats on the exterior, providing a backup option for use with manual wrenches or sockets.

This robust design makes them the go-to choice for professional automotive and heavy-duty industrial applications.

How to Use a Bolt or Screw Extractor Set Correctly

Используя болт extractor set correctly transforms a potential project-ending disaster into a manageable task. Proper technique is not just about success; it is about safety. Industry reports show that improper bolt loosening can lead to significant workplace incidents, from lacerations caused by a slipping wrench to falls. Following a methodical process ensures both a successful extraction and personal safety.

Step 1: Preparation and Safety

The initial preparation is the most critical phase for a successful extraction. Rushing this step often leads to broken tools and a more complicated problem.

Applying Penetrating Oil

Before any drilling begins, generously apply a quality penetrating oil to the seized fastener. The oil needs time to work its way into the threads to break down rust and corrosion. Allow it to soak for at least 15-30 minutes, or even several hours for extremely stubborn bolts. This single action dramatically increases the chances of a successful removal.

Using Safety Goggles and Gloves

Drilling into metal creates small, sharp shards of metal that can easily cause eye injury. Always wear safety goggles. Likewise, handling broken fasteners and tools can lead to cuts, so durable work gloves are essential. Safety precautions are non-negotiable.

Step 2: Drilling the Pilot Hole

A well-drilled pilot hole is the foundation for the screw extractor to work effectively. Precision here prevents the screw extractor from breaking.

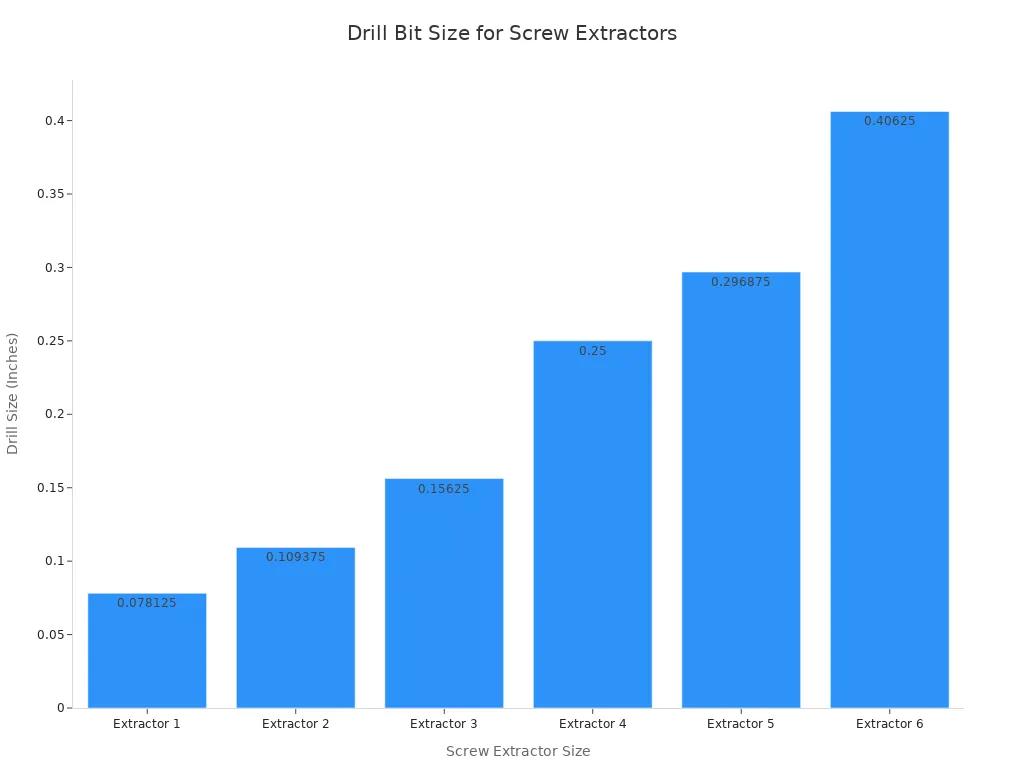

Выбор правильного размера сверла

Choosing the right drill bit is crucial. A hole that is too small will not allow the screw extractor to seat properly, while a hole that is too large will weaken the fastener walls. Most screw extractor sets provide a guide, but a standard reference is invaluable. A complete screw extractor and drill bit set often pairs these for convenience.

| Screw Extractor Size | Drill Size to Use |

|---|---|

| 1 | 5/64” |

| 2 | 7/64” |

| 3 | 5/32” |

| 4 | 1/4” |

| 5 | 19/64” |

| 6 | 13/32” |

Centering the Hole Accurately

An off-center hole applies uneven pressure to the screw extractor, making it likely to snap. To ensure a perfectly centered hole:

- First, create a flat surface on the broken fastener with a file or grinder if possible.

- Next, use a center punch and a hammer to create a distinct dimple in the exact center of the bolt. This dimple prevents the drill bit from “walking.”

- Begin drilling with a small pilot bit (e.g., 1/8-inch) before moving to the final recommended size. This progressive drilling technique helps maintain accuracy.

Step 3: Inserting and Turning the Extractor

With the pilot hole complete, the final step is the extraction itself. Patience is key to avoiding breakage.

Tapping the Extractor into Place

Select the correct size screw extractor from your screw extractor set. Insert its tapered end into the pilot hole. Use a hammer to gently but firmly tap the bolt extractor into the hole. The goal is to seat the screw extractor securely so its flutes bite into the walls of the pilot hole.

Applying Slow, Steady Counter-Clockwise Torque

Attach a T-handle or adjustable wrench to the end of the bolt extractor. Apply slow, constant, and even pressure in a counter-clockwise direction. Avoid sudden jerks of force. As torque is applied, the reverse threads of the screw extractor will dig deeper, gripping the stripped screw and forcing it to turn. Continue this steady rotation until the fastener is completely removed. This careful approach is the hallmark of professional work with all screw extractor sets.

Troubleshooting Common Issues

Even with the best tools and techniques, users can encounter problems. A broken screw extractor or a hopelessly seized bolt can stop a project cold. Understanding how to handle these issues separates a frustrating afternoon from a successful repair. These professional methods can help resolve the most common setbacks.

What to Do If the Extractor Breaks

A broken screw extractor inside a fastener is one of the most challenging repair situations. The hardened steel of the screw extractor makes drilling it out nearly impossible with standard bits. A methodical approach is necessary.

- Assess the Situation: Stop all work immediately. Do not attempt to force the broken piece.

- Use a Center Punch: Sometimes, the brittle nature of a screw extractor works to your advantage. Place a sharp center punch on the broken screw extractor fragment and give it a firm tap with a hammer. The shock can sometimes shatter the piece, allowing you to remove the fragments.

- Grind It Out: For a deeply embedded screw extractor, a more advanced technique is required. A technician can use a small, solid carbide burr bit with a high-speed rotary tool (like a Dremel). This process requires extreme patience and a steady hand. The goal is to carefully grind away the broken screw extractor without damaging the fastener’s threads. This difficult task highlights why quality screw extractor sets are a worthy investment. A cheap screw extractor is more likely to break under pressure.

This scenario is the ultimate test of a mechanic’s skill. Success depends on careful, precise work to remove the failed screw extractor.

When to Apply Heat to a Seized Bolt

Heat can be a powerful ally against rust and corrosion. Applying thermal energy causes the metal surrounding a bolt to expand, helping to break the bond holding the threads. However, this method requires extreme caution.

A user should apply heat only when penetrating oil fails. A propane or MAPP gas torch is the standard tool for this job. The heat should be applied to the housing or nut around the bolt, not directly to the bolt itself. This differential expansion is what breaks the fastener free. Heat the area for 30-60 seconds until it is hot to the touch.

Safety First: Never apply heat near fuel lines, plastic components, or wiring. Also, ensure any flammable penetrating oil has been cleaned off or has fully evaporated before introducing a flame. 🔥

After heating, allow the area to cool for a minute. This cooling process can help draw fresh penetrating oil into the threads. Then, insert the appropriate screw extractor from your screw extractor set and apply slow, steady torque. The combination of heat, cooling, and a quality screw extractor often overcomes even the most stubborn fasteners.

The Alden Grabit Pro Kit stands out as the best screw extractor for 2026. Its unmatched versatility handles both internal and external fastener damage effectively. For specific needs, other tools excel. The Topec Impact Set is the top choice for heavy-duty, high-torque jobs. The IRWIN HANSON set provides excellent value for reliable home project use. A user’s final decision on the best bolt extractor sets should depend on their primary application. Professionals need a durable, impact-rated extractor kit, while DIYers can choose a versatile, budget-friendly option from the best bolt extractor sets available.

Частые вопросы

Can a user reuse a bolt extractor?

Yes, a user can reuse a high-quality bolt extractor multiple times. Its lifespan depends on the tool’s material and the hardness of the fasteners it removes. Inspect the extractor’s cutting edges for wear before each use to ensure it remains effective.

What is the difference between a screw and a bolt extractor?

The terms are often used interchangeably. Most extractor sets work on both screws and bolts. The key is matching the extractor size and type to the specific damaged fastener. A “bolt extractor” often implies a tool designed for larger, higher-torque applications.

Does a user need an impact wrench for all extractors?

No, an impact wrench is not always necessary. Many extractors, like spiral and straight flute types, require manual tools for controlled torque. Only use an impact wrench with extractors specifically marked as “impact-rated” to prevent tool failure. ⚠️

Why did my extractor break?

Extractors typically break for a few common reasons:

- Using a non-impact extractor with an impact wrench.

- Applying sudden, jerky force instead of steady torque.

- Drilling an off-center or incorrectly sized pilot hole.

- Using a low-quality tool on a hardened bolt.

Can an extractor remove a left-hand thread bolt?

Standard extractors have left-hand threads and will not work on left-hand threaded bolts. They would tighten the bolt instead of loosening it. A user needs a special right-hand threaded extractor for this rare situation.

What is the best extractor for very small screws?

For small screws found in electronics or glasses, a micro-extractor set is the best choice. The Alden Grabit Micro Extractor Set is an excellent example. These tools are specifically designed for precision work on tiny, delicate fasteners.